How It Works: Noise Reduction Ratings

Considering Hearing Protection Devices (HPDs) for your employees? You’ve probably seen the Noise Reduction Rating (NRR) label on packaging or in product descriptions. But what is a noise reduction rating? How do you calculate it? Do bigger numbers mean better hearing protection?

A BRIEF HISTORY OF NOISE CONTROL

Congress passed the Noise Control Act of 1972 to address “…a growing danger to the health and welfare of the Nation’s population.” The Act empowered the U.S. Environmental Protection Agency (EPA) to develop Federal noise emission standards, and to regulate permissible noise exposure.

In 1979, EPA introduced its Noise Label Program. Its goal: to help consumers identify products that “produce noise capable of adversely affecting public health or welfare, and…products sold to reduce noise.”

Labeling requirements affect both loud equipment like air compressors, and devices that claim to reduce noise and protect the wearer’s hearing. Noise-emitting products require a Noise Rating label. HPDs must display a Noise Reduction Rating label.

WHAT IS A NOISE REDUCTION RATING?

Simply put, an NRR number represents how much noise is reduced by the proper use of a hearing protection device. In general, bigger numbers represent more noise reduction.

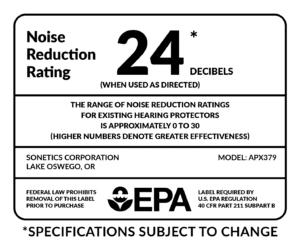

As with most tests, there is more than one way to interpret results. The certified laboratory NRR number appears on the current EPA-mandated label (see Fig. 1). There’s also an ‘effective’ adjustment you can calculate that tries to represent what a range of people might experience with every-day use of the same device.

NRR IN THE LABORATORY

EPA regulations require the use of ANSI STD S3.19-1974 to determine the amount of sound reduction or “attenuation” provided by an HPD. First of all, test subjects are exposed to specific sound levels and frequencies first with ears open, and then while wearing the hearing protection device being tested. Trained lab techs fit the HPD onto each test subject to ensure that it is worn according to the manufacturer’s instructions. Technicians conduct multiple tests.

The differences in the ‘with’ and ‘without’ tests (and a lot of math in between) represent the amount of noise reduced by the HPD. The final number appears on the EPA-mandated NRR label for the device (Fig. 1).

‘REAL WORLD’ NOISE REDUCTION

There can be significant differences between a controlled, lab environment and the ‘real world’. If a user doesn’t follow proper procedures when fitting their HPD, the device won’t reduce as much sound as the NRR rating implies. Overestimating noise reduction can lead to inadequate protection, hearing damage and hearing loss.

Recognizing this, OSHA and others came up with ways to estimate how effective an HPD is likely to be in the hands of the less experienced.

Let’s say the equipment you’re monitoring is putting out a steady 95 decibels (dB). Luckily, you’re wearing an HPD that has an NRR of 24dB. You quickly subtract 24 from 95 and get 71, right?

Not quite. One real world formula for calculating an effective attenuation subtracts seven (7) from the laboratory NRR and then divides the result by 2 (called ‘derating’). Start with the NRR of your hearing protection device: 24. Subtract 7. Now we’re at 17. Divide 17 by 2, which is 8.5. Now subtract 8.5 from the original sound at 95, and you have an effective sound exposure of 86.5dB.

WHICH RATING METHOD IS THE BEST?

Laboratory NRR is an important baseline comparison. Even so, there are other important factors to consider, such as “…comfort, compatibility with safety equipment, communication needs, and ease of use…” that users may not consider if they rely solely on a device’s NRR.

If your employees don’t or won’t wear an HPD—whether it’s due to comfort, ease of use, or features—it really doesn’t matter that the device’s rating is 1 point higher.

Derating is more helpful in comparing HPD performance against a specific noise source, like the diesel engine of a combination truck. But general derating methods don’t consider that certain types of HPDs are easier to wear properly than others (over-the-ear muffs versus in-the-ear plugs). The “divide by 2” step instead reduces all HPD ratings by 50%. Arguably, earplugs should be ‘derated’ more than earmuffs.

In the end, both numbers are only a starting place to help you make informed safety equipment choices for your employees. Once you’ve made your selection, the real work begins: workplace adoption.